Cook Medical invoicing programme helps LKH-University Hospital Graz lower costs

The situation

When a new head of procurement started in Bradford Teaching Hospitals NHS Foundation Trust in 2012, he was tasked with delivering substantial savings back to the trust. He knew this task would require more than just cutting deals on line-item product pricing. He planned to approach relationships with suppliers differently and save costs by creating a more efficient business relationship. He needed to accomplish this without investing in large capital purchases or expensive software. He wanted the procurement department to become more than a ‘supplies department’ and to add greater value to the trust. All of this would require cultural change.

Willing to work

The head of procurement wanted to approach supplier relationships holistically and discover where value could be found in areas other than in line-item product pricing. The procurement team approached suppliers, but many were uninterested in working this way. Cook Medical’s Healthcare Business Solutions (HBS) team approaches procurement relationships differently. When Bradford saw that Cook was willing to work in a new way, the foundation for a new relationship was laid.

A methodical approach

The corporate account executive for Cook Medical first wanted to understand Bradford’s needs and develop a plan to achieve cost savings. Cook quickly learned that identifying savings opportunities for the Endoscopy department was a high priority. Cook developed a product conversion plan that Bradford accepted. Then Cook methodically introduced products for clinical evaluation, month by month, according to Bradford’s priorities. Strict attention was paid to product evaluations at the end of each month, so that Cook could provide necessary product education and training.

The full evaluation process took more than nine months and included periodic face-to-face discussions between Cook’s HBS team, Bradford’s clinical team, and Bradford’s procurement team. At the end of the evaluation process, Bradford was able to convert to Cook’s Endoscopy line of products. The conversion resulted in consolidated inventory and reduced costs for some commodity products. These savings allowed Bradford to purchase some premium technologies without impacting its budget. Patients, clinicians, and the supply chain all benefited from the improved partnership between Cook and Bradford.

Beyond conversion

Although the conversion of the Endoscopy product line saved approximately £40,000, both Cook and Bradford felt that the greatest benefit of the project was the trusting and transparent relationship that they built. The success of the Endoscopy conversion led to similar projects in other clinical departments of the hospital such as Urology. Cook and Bradford have also initiated several efforts for supply chain improvement. The organisations worked on an e-procurement strategy, through the Global Healthcare Exchange, to cleanse catalogue data and reduce errors in purchasing and invoicing. Now 99.58% of Bradford’s orders with Cook are error-free and employees no longer need to spend their time fixing error-filled orders. To continue to create savings, Bradford and Cook are planning future initiatives such as data standards adoption and inventory management.

The results

After four years of approaching their procurement relationship differently, Bradford and Cook agree that doing business together is easier and more productive. Several future clinical and procurement initiatives promise to deliver additional shared cost savings.

“It was hard to get medical suppliers to buy into this new and unconventional model as it required them to change their working relationships from having multiple local reps who are focused on clinical sales and relationships only to a central account management structure. Cook Medical was the first supplier who embraced this new model and supported the trust with this approach. As a result, BTHFT have been able to improve contract prices, contract compliance and coverage, introduce new innovative products, streamline the order process, reduce carriage charges, and improve carbon footprint impact on the trust”

—Mr. Ali Ali, Head of Procurement Bradford Teaching Hospitals NHS Foundation Trust

Contact us

For more information or to speak with one of our Healthcare Business Solutions team members, please e-mail us at info-EMEA@cookmedical.com.

Click on image to download the full story:

The situation

Like all NHS Trusts, Royal Berkshire NHS Foundation Trust was tasked with achieving annual cost savings. As a major supplier, Cook Medical was asked to explore ways to support the trust’s savings agenda. Although the trust’s endoscopy unit manager and Cook’s endoscopy division sales representative had a strong clinical relationship, this was the first time that the trust’s senior management team and Cook’s Healthcare Business Solutions team had worked together.

To assist with the trust’s savings initiative, Cook reviewed its full product range and submitted new proposals to help deliver cost savings. During this process, the head of procurement highlighted endoscopy as an area with specific cost pressures and challenged Cook to find a quick solution to the problem. Delivering a viable solution would be crucial to the relationship between the two parties.

A collaborative effort

Cook’s corporate account executive and its endoscopy’s corporate account manager immediately convened a meeting of key clinical and business stakeholders from Cook and the trust. The head of procurement, who had learned that the clinical team held Cook products in high regard, considered how collaboration between clinical and procurement personnel in endoscopy could deliver the required savings. The trust’s endoscopy unit manager was quick to support this idea and extoll the clinical value of Cook devices and the trust’s relationship with the Cook sales representative.

When the parties reached a consensus, the trust felt confident that it could maximize its savings potential by converting to more of Cook’s endoscopy product range. With the support of the trust’s clinical team, product trials and evaluations took place across the product range to ensure that the products met the trust’s needs.

The result

Cook worked closely with the trust’s endoscopy unit manager and purchasing department to submit a revised financial offer for the product range. The trust stands to gain £26,500 in annual savings in the endoscopy division.

Contact us

For more information, or to speak with one of our Healthcare Business Solutions team members, please e-mail us at info-EMEA@cookmedical.com.

Click on the image to download the full story:

The situation

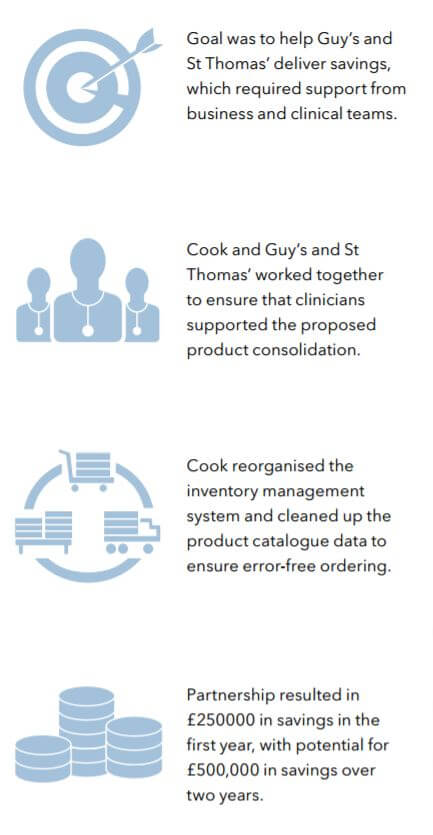

The chief procurement officer at Guy’s and St Thomas’ NHS Foundation Trust in London was looking for new ways to save costs in the supply chain through more strategic relationships with suppliers. Historically, supplier relationships were focused on unit price and the trust wanted to pursue wider process efficiency opportunities and structured clinical engagement. Cook Medical was one supplier that the trust challenged to establish a different kind of partnership.

At their first meeting, it was obvious that Cook could help Guy’s and St Thomas’ make substantial cost savings, but both parties quickly realised they would need to approach their relationship differently than they ever had before.

A holistic approach

Cook approached Guy’s and St Thomas’ with a proposal, which would allow them to reduce the number of suppliers they purchased products from and improve their existing supply chain. Consolidating products required the support of the lead clinicians as well as the procurement team. Cook’s representatives supported the conversion through planned evaluations ranging from lab time to full product evaluations with the trust’s doctors in the radiology department. The clinicians were happy with Cook’s product offering, even discussing further product conversions in the future.

Supply chain efficiency

The other important part of the cost-savings project was stock management. Guy’s and St Thomas’ was using two different systems to track consignment stock through the system, which was leading to confusion about where products were located and if they were close to expiring. It also introduced the potential for high-value stock to go out of date, which was costly to the trust. The clinical team was frustrated—a common view was that they “had the product we want…somewhere”—but the incompatible systems were inconvenient and inefficient.

Helping Guy’s and St Thomas’ manage its stock meant completely overhauling its product inventory across multiple clinical divisions. This process involved converting high-usage items from consignment to purchased stock, which lowered cost for the trust, and refreshing any remaining consignment items with new stock. Cook worked with the trust’s supply chain team to cleanse the catalogue data and ensure error-free ordering, and to fully optimise the trust’s automated inventory management system, Smartstore. They also set new stock holding levels that were based on historical product usage. These efforts reduced clinical frustration and administrative costs and helped to ensure that the right product was in the right place when needed.

The result

The collaboration between the three parties—Cook, the procurement team, and the clinical team—represented a positive change in the relationship between Cook and Guy’s and St Thomas’. The two organisations have committed to periodic business review meetings to ensure that their current cost-savings efforts continue and to identify new opportunities in the future. Strong communication continues between the procurement team, clinical team, and Cook to ensure that the savings target is reached.

The initial changes made between the trust and Cook have successfully reduced costs and improved efficiencies for both organisations. The clinical awareness of the full Cook product offering for the radiology department has allowed for product and supplier consolidation. The stock management and inventory issues have improved significantly. In the first year after making the change, the trust saved an estimated £250,000, and the savings is expected to be the same for the second year.

To hear more from Guy’s and St. Thomas’ listen to their chief procurement officer, David Lawson, tell his story here.

4265016785001

brightcove

true

Click on image to read the full story:

In a time when healthcare is under tremendous pressure to reduce the costs and deliver efficiency, we think working together is more important than ever. Read how our partnerships with customers have created significant improvements in how we do business together.

Bradford Teaching Hospitals NHS Foundation Trust

Bradford Teaching Hospitals NHS Foundation Trust

When a new head of procurement started in Bradford Teaching Hospitals NHS Foundation Trust in 2012, he was tasked with delivering substantial savings back to the trust. He knew this task would require more than just cutting deals on line-item product pricing. He planned to approach relationships with suppliers differently and save costs by creating a more efficient business relationship.

LKH-University Hospital Graz

LKH-University Hospital Graz

A member of Cook’s Healthcare Business Solutions team met with the finance director of LKH-University Hospital Graz to determine how they could create efficiencies. They discovered that the hospital received more than five hundred Cook invoices each year. Each invoice cost the hospital €56 to process.

Royal Berkshire NHS Foundation Trust

Royal Berkshire NHS Foundation Trust

Like all NHS trusts, Royal Berkshire NHS Foundation Trust was tasked with achieving annual cost savings. As a major supplier, Cook Medical was asked to explore ways to support the trust’s savings agenda.

Guy’s and St Thomas NHS Foundation Trust

Guy’s and St Thomas NHS Foundation Trust

This trust wanted to pursue wider process efficiency opportunities and structured clinical engagement. Cook Medical was one supplier that they challenged to establish a different kind of partnership.

Lean tools can foster efficient customer–supplier partnerships

Lean tools can foster efficient customer–supplier partnerships

In the latest edition of National Health Executive (NHE) magazine, Paula Culliton, LSS Black Belt and project manager with Cook Medical, explores how NHS procurement departments and their suppliers have much to gain from adopting an end-to-end, collaborative approach in their shared supply chain processes.

The situation

Health spending in Austria continues to rise, and hospitals are highly motivated to improve cost-efficiency. The LKH University Hospital Graz is no exception. Cook Medical has supplied LKH-University Hospital Graz with products for many years. However, Cook and the hospital’s business managers had not worked together very closely. A member of Cook’s Healthcare Business Solutions team met with the finance director of LKH-University Hospital Graz to determine how they could create efficiencies. They discovered that the hospital received more than five hundred Cook invoices each year. Each invoice cost the hospital €56 to process. The hospital’s annual cost to process the invoices was €30,000.

One invoice a month

Cook and the hospital worked together to make invoicing more efficient. The hospital would receive one invoice per month for all Cook products that were purchased across all of the hospital’s departments. This more efficient method of invoicing was presented to the financial director at the hospital and the team responsible for invoicing at Cook. After a successful test of the new invoicing method, Cook and the hospital changed to monthly invoicing.

“A small change in our ordering and invoicing structure ensured a substantial amount of cost reduction per year without any change in our high standard of care for our patients. All it needed were two short meetings with Cook and a short test run for the new invoicing process to be successfully implemented.”

—Mag. Gebhard Falzberger, Executive Director, LKH-University Hospital Graz

The result

The LKH-University Hospital Graz saved more than €22,000 annually by a consolidating the number of invoices that it receives. This programme delivered savings without affecting clinicians and patients. This change required only two meetings with the hospital’s financial director and one meeting with the invoicing control team.

“Cook is one of our most reliable business partners and even helped us to identify a substantial cost efficiency potential. Because of this quick and successful cooperation with Cook, we will contact our other business partners and try to engage them also in finding similar solutions for more cost efficiency.”

—Mag. Elke Schnedl-Lamprecht, Head of Finance, LKH-University Hospital Graz

Contact us

For more information or to speak with one of our Healthcare Business Solutions team members, please e-mail us at info-EMEA@cookmedical.com.

Click on image to download the full story: